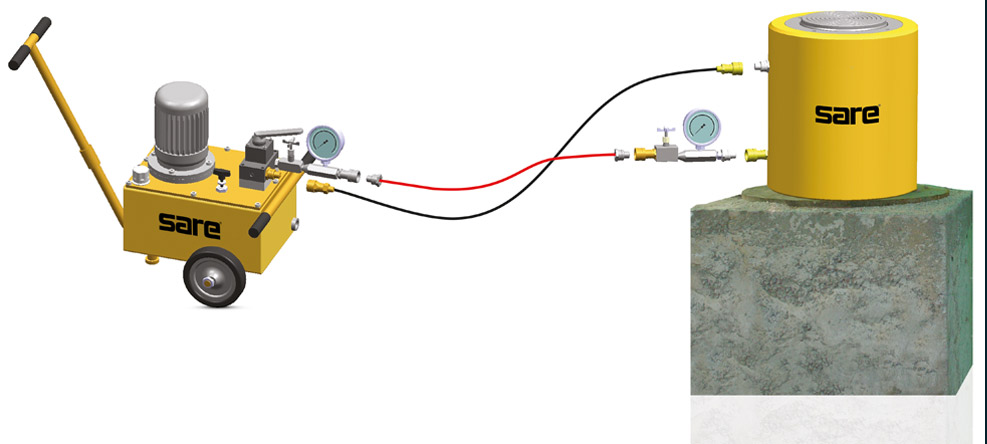

Special directional valve system in the power pack of the pile test system, shut of valve and calibrated gauge.

The gauge set-up aiming to observe the vertical motions at the top of the pile during the test, to get periodical records and it’s frame is fixed to the outside of the impact area.

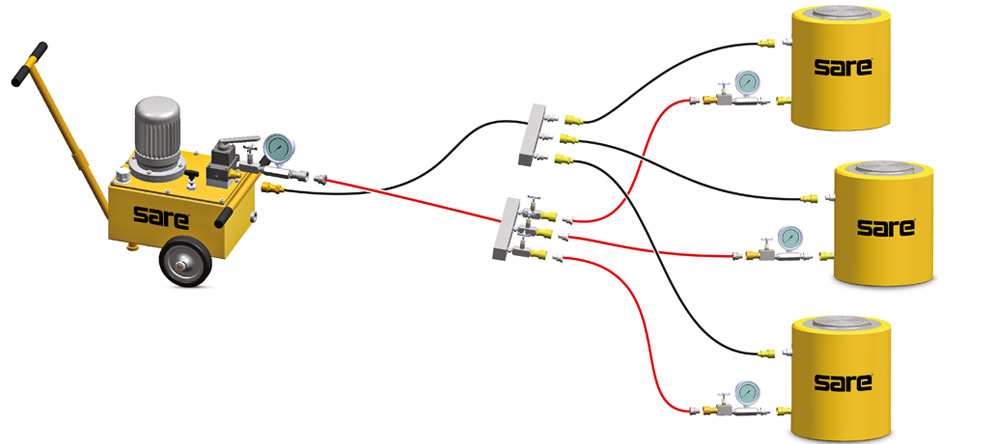

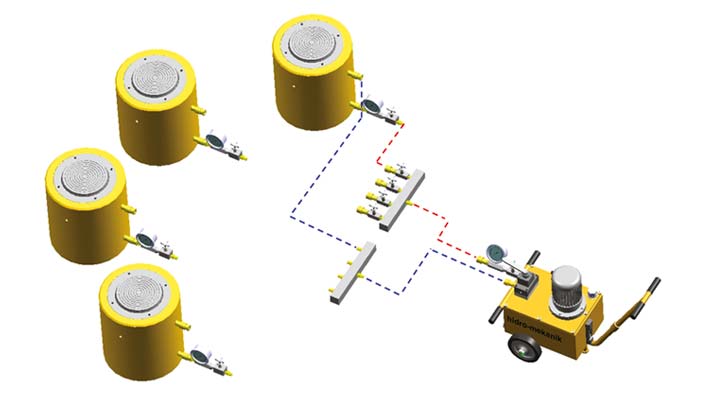

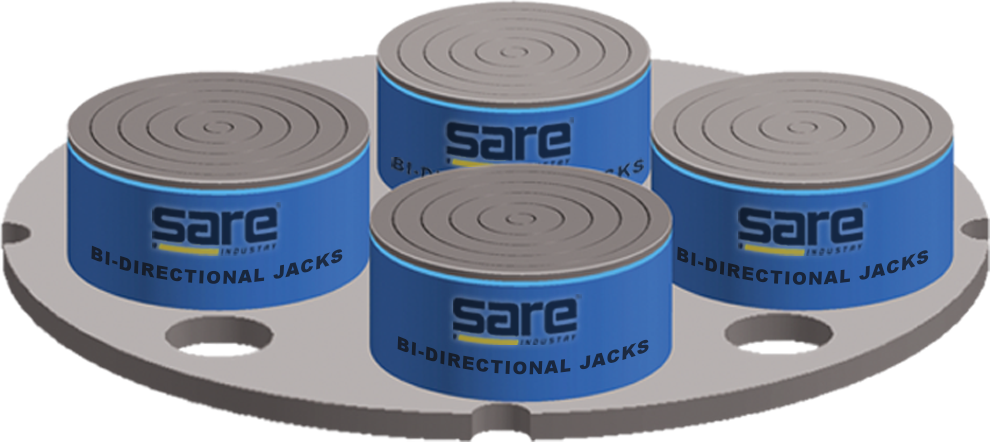

Pile Loading Tests with multiple cylinder groups are operated with single electric hydraulic power units designed according to the capacity determined according to the number of cylinders and tonnage.

In the system, which works with the help of manifolds selected according to the number of cylinders, all of the cylinders can be used simultaneously or independently of each other. In this way, the same pump with different numbers of cylinders can be used in different tests (as long as its capacity is available).

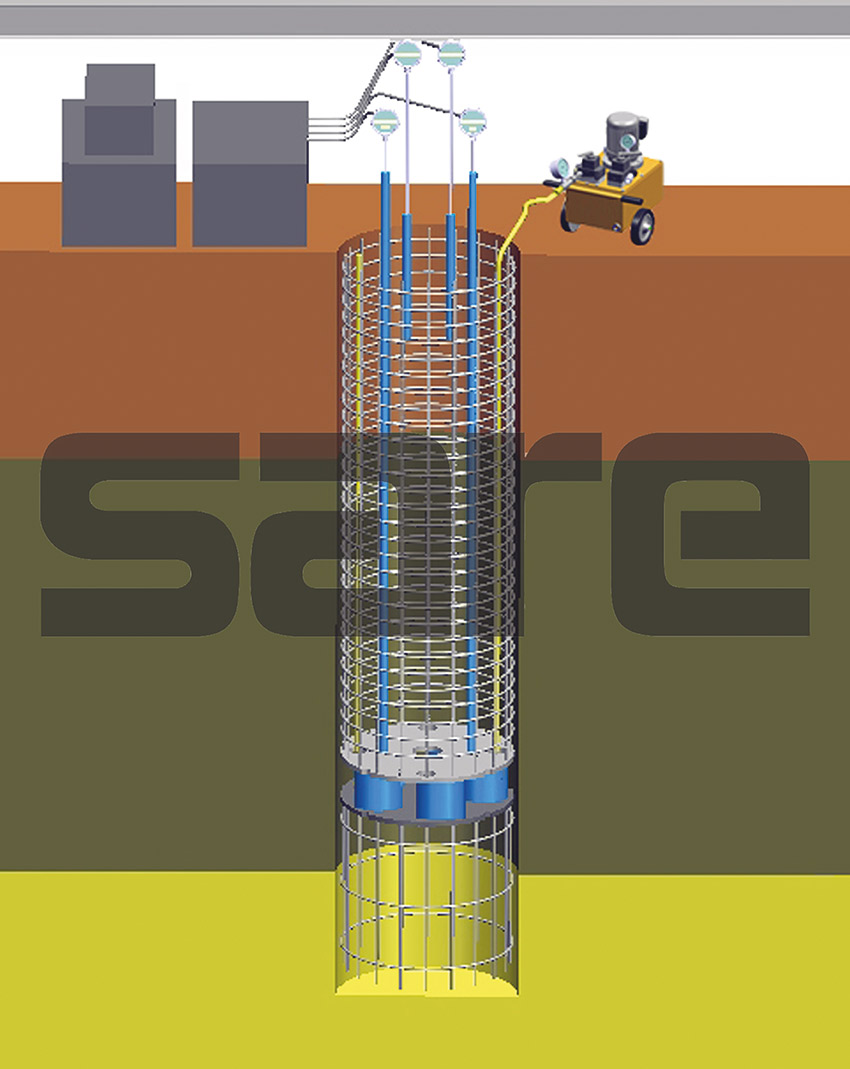

Bi-Directional Load Test

Bi-DirecIonal Static LoadTest is truly an innovative static load testing technique. It is the only load test that provides separate measurement of a pile’s end bearing and skin friction. The reaction system in Bi-Directional Static Load Test derived from the soil and or rock along and below the drilled shaft, hence the system is not restricted by the limits of overhead structural beams, large kentledge, tie-down reaction piles and deep cut of level as in the conventional top loaded static load test system.

SARE GLOBAL operates under the same group as one of the world’s leading manufacturers of both Static pile testing systems and Bi Directional Test systems.

SARE GLOBAL is responsible for the design, production and quality control, testing and calibration processes of the hydraulic jacks being produced. It is the world supplier of many implementing companies by combining the jack design and manufacturing quality, which should be at the highest level, especially for Bi Directional Pile Test systems, which are rapidly becoming widespread all over the world, with a sustainable supply infrastructure for many years.